Every multifamily project is designed with our BIM software by a team of designers who primarily have had extensive experience working as carpenters. Each contracted project has a salaried team assigned consisting of:

- Project Manager

- Lead BIM designer

- Field Superintendent

- Pick up foreman

- Team production lead’s for framing, joisting and sheeting

- All of our management and design teams are English speaking

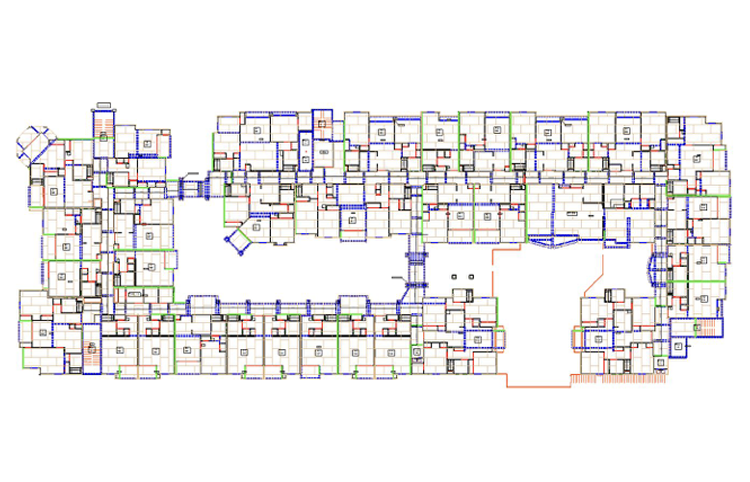

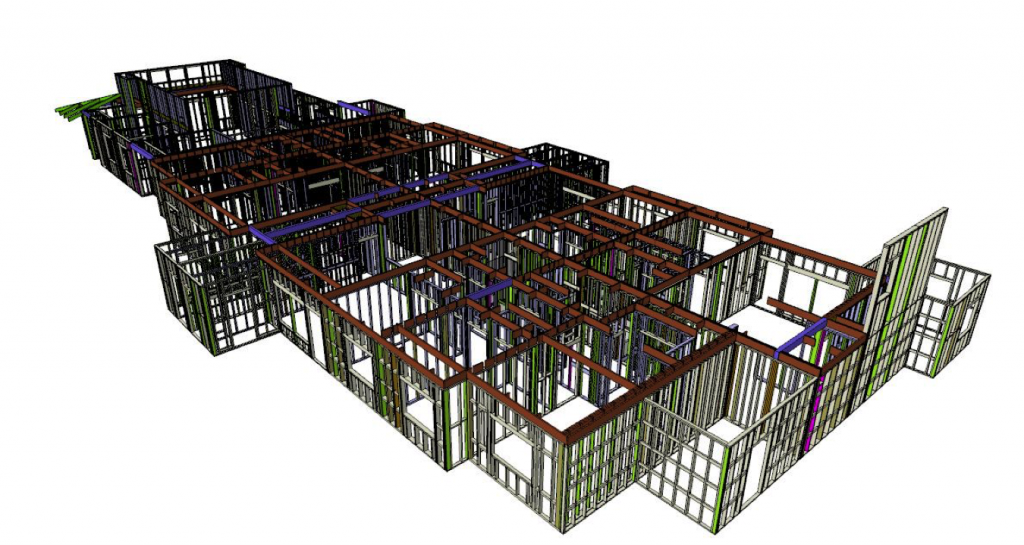

Design Method

We use a BIM (Building Information Modeling) environment to model and coordinate rough framing issues such as: architectural requirements vs. structural, plumbing, HVAC, and electrical.

Using BIM, up to 95% of the framing issues can be resolved. After which, we can then build the major structural framing components at our off site facility.

- Vetting majority of the issues prior to construction.

- Team interacts in advance during cooperation process.

- Coordinated model is utilized in the field directly.

- Coordination process potentially saves time on critical path and schedule.

- Cost savings related to future CO reduction.

Framing Methods

SPEEDY-FRAME™

- BIM design & Coordination

- Laser edge plate layout

- Precision trim components

- Walls manufactured on-site

Good for sites that have certain restrictions or environmental challenges.

PANELIZATION

- BIM design & Coordination

- Laser edge plate layout

- Precision trim components

- Walls manufactured off-site

Consistent layout and framing unit to unit and floor to floor. Significant time saving on critical path.